Our Hands-on experience and extensive technical Knowledge of various processes enable us to provide thermal solutions like Multiple effect Evaporator(MEE) & Dryers for Zero Liquid Discharge System(ZLD).

It is important to study and understand the characteristics of effluent before designing the system. Mega Engineering provides process studies, laboratory testing, Complete process design engineering packages and process audits to deliver the best possible solutions.

Features

– Effluent Specific Combination of various type of evaporators.

– Heat integration for low energy requirement.

– The well-designed system reduces operating & disposal costs

– Modular skid mounted plants can also be provided under Client’s request to save project execution time & site work.

– Stripper column combined ZLD system to de-gas the volatiles to reduce the BOD/COD load on secondary or tertiary treatment.

Our Offerings

– Falling Film Evaporator

– Rising Film Evaporator

– Forced Circulation Evaporator

– Agitated Thin Film Dryer

– TVR/MVR – Thermal/Mechanical Vapour Recompression

– Agitated Thin Film Evaporator

– Condensate Polishing Unit (CPU)

– Stripper Columns

– Solvent recovery Columns

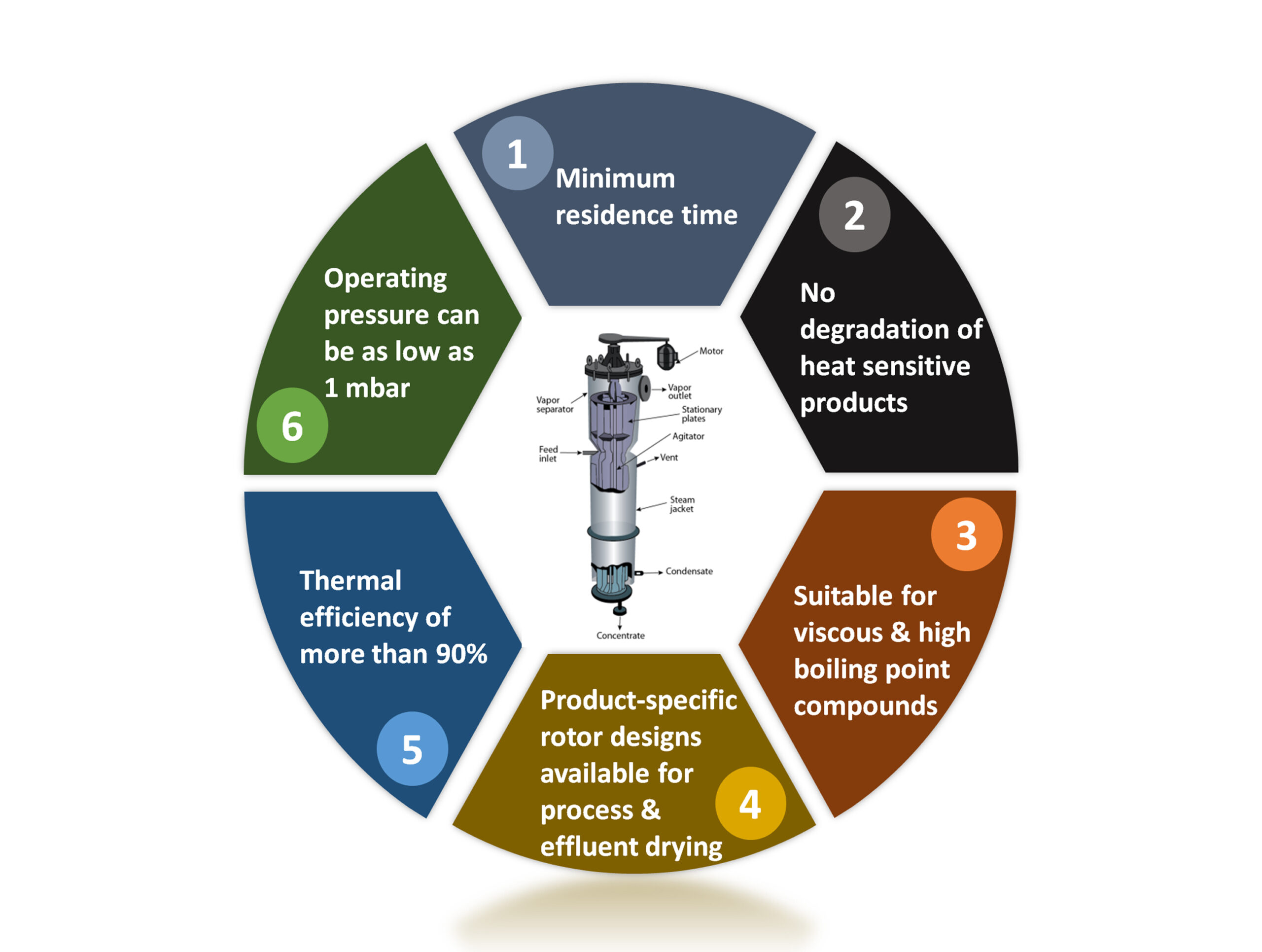

Benefits of Agitated Thin Film Dryer

Process Condensate Polishing Unit (PCPU)

To recycle condensate back to process, it is necessary to treat it up to maximum extent matching required process parameter. The condensate from evaporation plants must be purified in a condensate polisher to convert a waste stream into good quality water which can be reused as a process, cooling, rinsing, boiler feed water.

Various treatments as followed:

• Neutralization.

• Aerobic & Anaerobic Processes.

• Carbon adsorption.

• Ultrafiltration (UF).

• Reverse Osmosis (RO)