Mega is currently offering Great answers for ethanol production plant from various raw materials. Processes are tailor made to fit local conditions and quality of feedstock. Our flexible designs can handle multiple feedstock in the same plant to produce various grades of alcohol.

We can handle the following feedstock –

STARCH BASED FEEDSTOCK:

Grains : Corn, Wheat, Broken rice, Sorghum, Rye, Millet, etc.

Tubers : Cassava, Tapioca,Potato

Other : Waste starch slurries

SUGAR BASED FEEDSTOCK:

Molasses : Molasses grade A, B and C

Sugarcane : Sugarcane juice, Sugarcane Syrup etc.

Dates : Fresh and Waste dates

Others : Sweet sorghum

Best quality product, lowest possible OPEX consistency in product quality and ease of operation are the key features of “Mega-Efficiente" distillation technology.

We offer customized distillation system to comply with client's requirement to produce different grades of alcohol with minimum impure spirit production.

MEGA – “CONTINUO"

– Easy to operate

– High yield

– Continuous fermentation

– Consistent yield

– Suitable for sugary feedstock

MEGA – “RECICULAR"

– Recycle up to 65% raw vinasse

– Continuous Process

– Lowest water consumption

– Lowest power consumption

MEGA – “SIF"

– High Alcohol concentration up to 15%

– Most suitable for grain

– Without or with Jet Cooker

– Auto cleaning

– CSTR design

OUR OFFERINGS :

Fermentation Technologies

– MEGA – CONTINUO

– MEGA – RECICULAR

– MEGA – SIF

Distillation Technologies

– MEGA – Efficiente

– MEGA – Pure

Dehydration Technologies

– MEGA – PSA

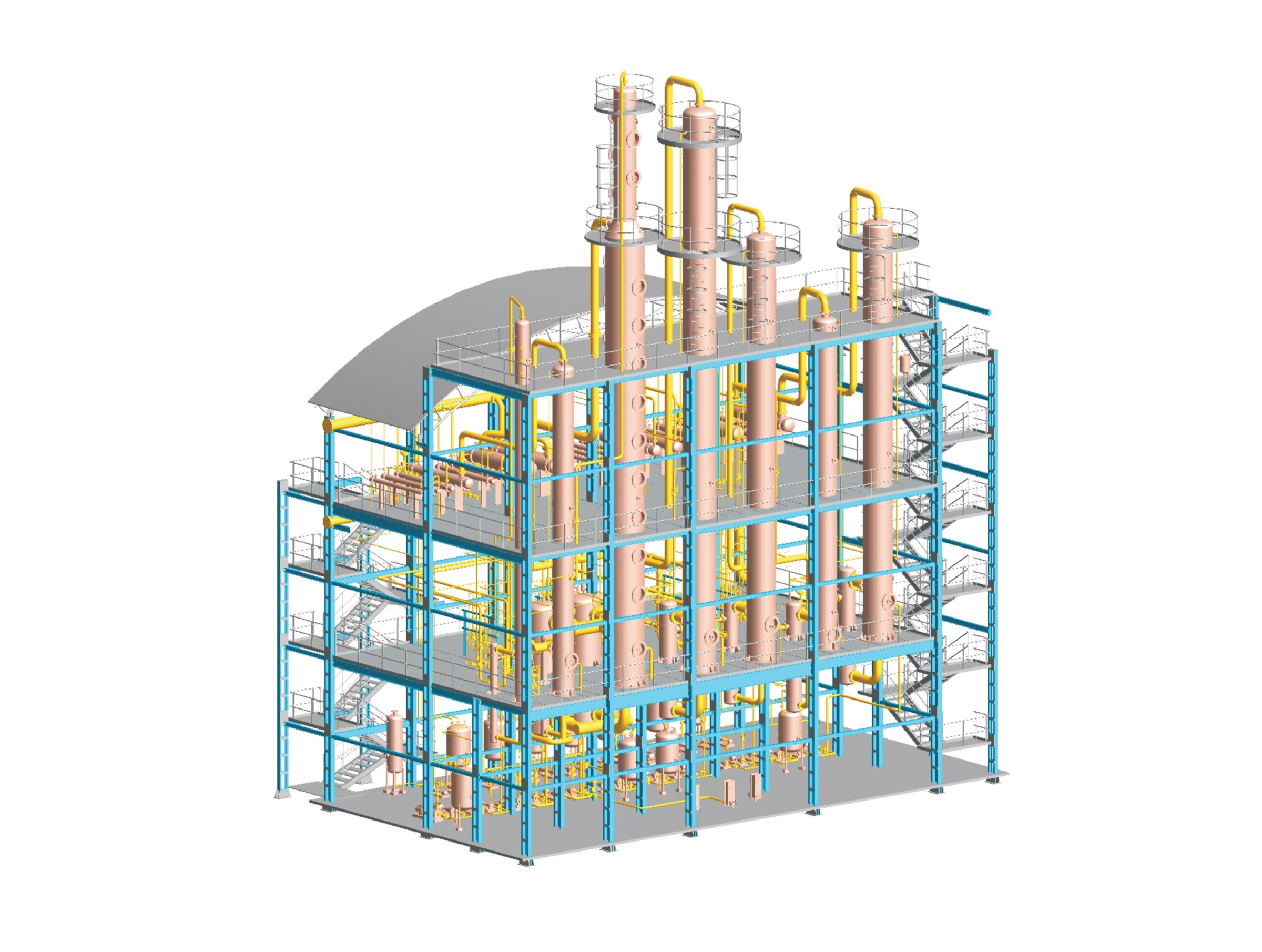

MEGA-“Efficiente" :

This system is designed with objective of low steam consumption using Vacuum-Pressure combination of Distillation Columns.

MEGA – “Pure" :

To produce extra pure Potable grade/ Extra neutral alcohol, this is the most suitable technology. Optimum use of copper, proper reflux ratios, efficient hydro-extraction distillation ensures best quality alcohol.

MEGA – “PSA" :

Based on Pressure Swing Adsorption technology using 3Å molecular sieves with lowest energy consumption using best heat integration. Fully automatic plant, simple and easy to operate. Mega-PSA ensures high ethanol dryness and long life of molecular sieves.

Process Upgradation

With an experienced team of alcohol/distillery plant experts, strong engineering back up and innovative ideas, we offer services of plant up-gradation & expansion to reduce production cost, save energy, reduce effluent load. Our innovation and solutions have proved helpful to our customers to earn extra profits.

Our distillery up-gradation services include the following –

• Upgrading batch fermentation to continuous

• Upgrading atmospheric distillation to multi-pressure distillation.

• Increase capacities of plant without changing existing set up.

• Improvement in alcohol quality

• Reducing effluent volume

• Improvement of alcohol yield

• Automation & control

• Integrated Evaporations.

And many more….

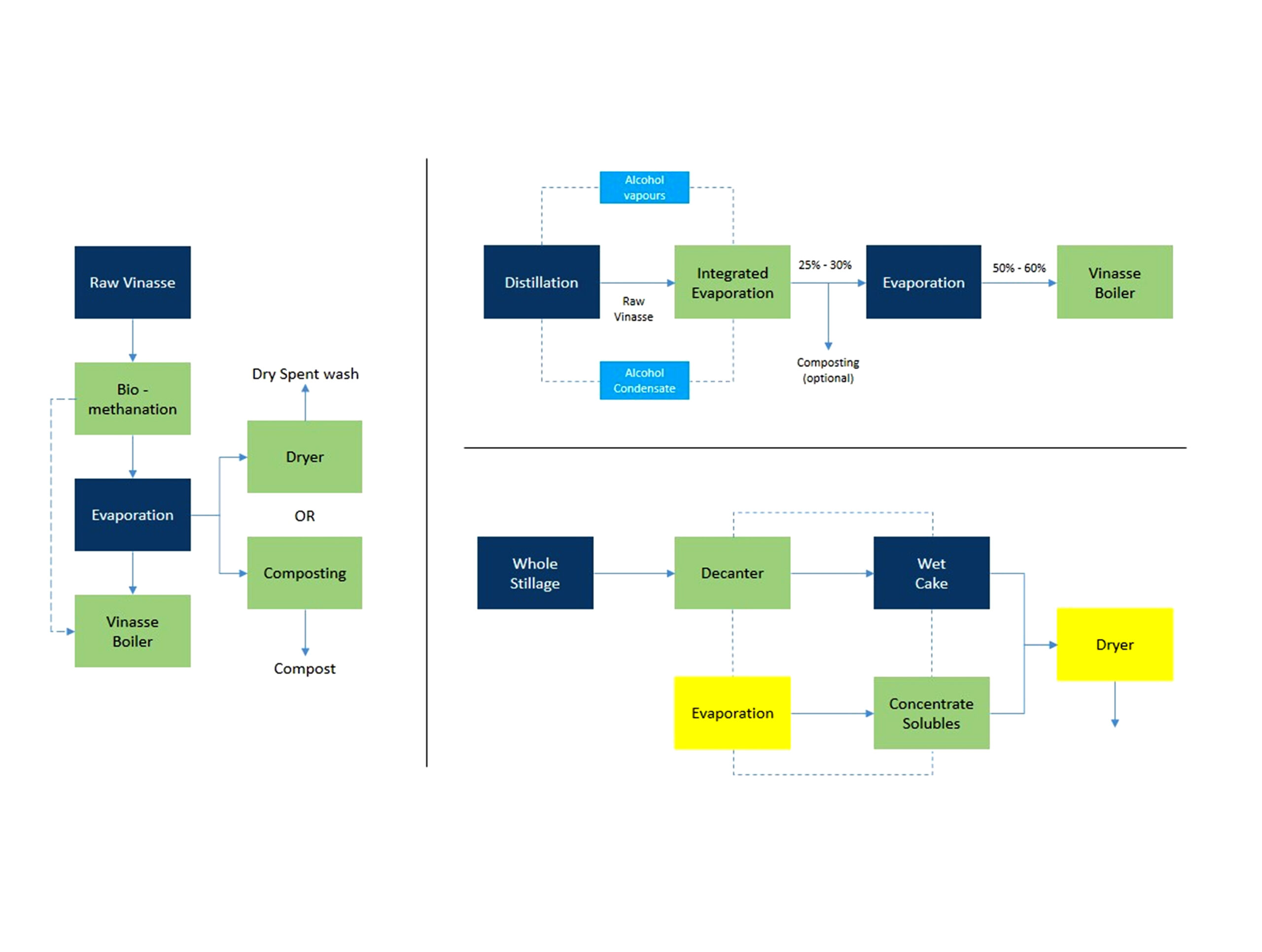

Waste Water Solutions

Reduce, Reuse, and Recycle. The 3R is the need of the hour for the whole world. Integrated energy solutions by Mega Engineering not only address the environmental concerns but also reduce your operational costs. Based on the local conditions and client's requirement, the solution is chosen.