In case of multiple-effect evaporation plants, the exhaust vapors from the product are used to heat the downstream-arranged evaporation effect so that the steam consumption will be reduced accordingly.

MEGA evaporation plants are designed to efficiently conserve and utilize steam in the most effective way possible. With increasing energy costs and environmental demands, there is a greater need for energy-efficient evaporators that can also segregate condensates so that the water can be reused. MEGA offers complete system for treating liquid streams and processing the condensates for optimal re-use, while minimizing energy consumption.

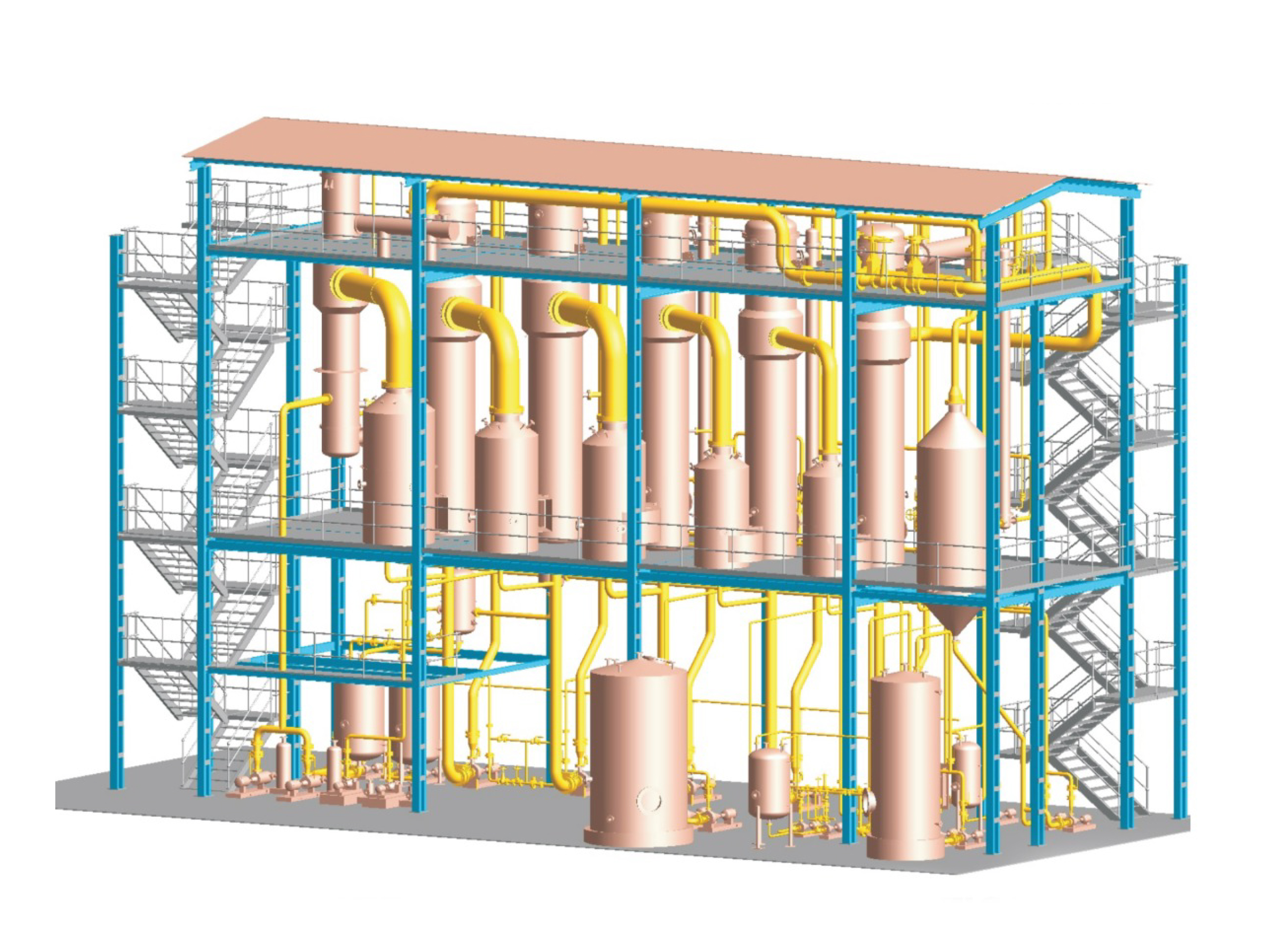

Our evaporators systems are tailor made which can easily be integrated or also standalone, combination of falling film, forced circulation and agitated thin film type with lowest operating & maintenance cost. Trouble free non-stop operations are key of profitable businesses of our clients.

We offer various types of evaporator and each type has its unique benefits, the most suitable type of evaporation technology is selected for our customers with consideration of the process parameters for instance scaling tendency, product thermal sensitivity, annual operating hours and accessibility for maintenance.

Features

-Vinasse concentration upto 70% using low pressure steam or alcohol vapours.

– Effective use of TVR/MVR in Evaporation, whenever required.

– Energy efficient Evaporation plant-Integration with Distillation.

– High Efficient Vapour liquid Separators/Mist Eliminators for Lower TDS in Condensate.

– Operator Friendly.

– Less area/foot prints required.

– Fully Automatic Plant.

Our Offerings

– Falling Film Evaporator

– Forced Circulation Evaporator

– Agitated Thin Film Dryer

– TVR- Thermal Vapour Recompression

– MVR-Mechanical Vapour Recompression

Applications

• Pharmaceutical Industry

• Dairy Industry

• Waste Water treatment

• Vinasse/Dryer for Spent Wash Concentration